Choosing between manual-assisted and fully automatic stretch wrapping machine

Choosing between manual-assisted and fully automatic stretch wrapping machine

Blog Article

Let loose Performance in Your Warehouse Operations With a Premium Stretch Wrapping Maker

Productivity in stockroom operations rests on the performance of the packaging process. The intro of a top notch stretch covering device can be a game-changer, encouraging effectiveness, minimized labor prices, and minimized human error. With the capability to handle different load dimensions and wrap many pallets per hour, these devices offer a compelling proposition for any kind of organization looking to optimize its operations. So, what makes these makers such an essential property in warehousing? Let's explore additionally.

Understanding the Duty of Stretch Wrapping Machines in Stockroom Operations

In the substantial realm of stockroom operations, the value of stretch covering devices can not be overstated. They serve a crucial function in making certain that items are securely and firmly bundled for storage space or transport. These equipments use an extremely stretchable plastic movie around products, tightly wrapping them together in such a way that hands-on wrapping simply can not match.

Stretch wrapping makers can deal with huge quantities of products quickly, substantially speeding up the packing process. The consistent covering provided by these devices can decrease the danger of tampering or burglary throughout transit.

Secret Functions of High-Quality Stretch Wrapping Machines

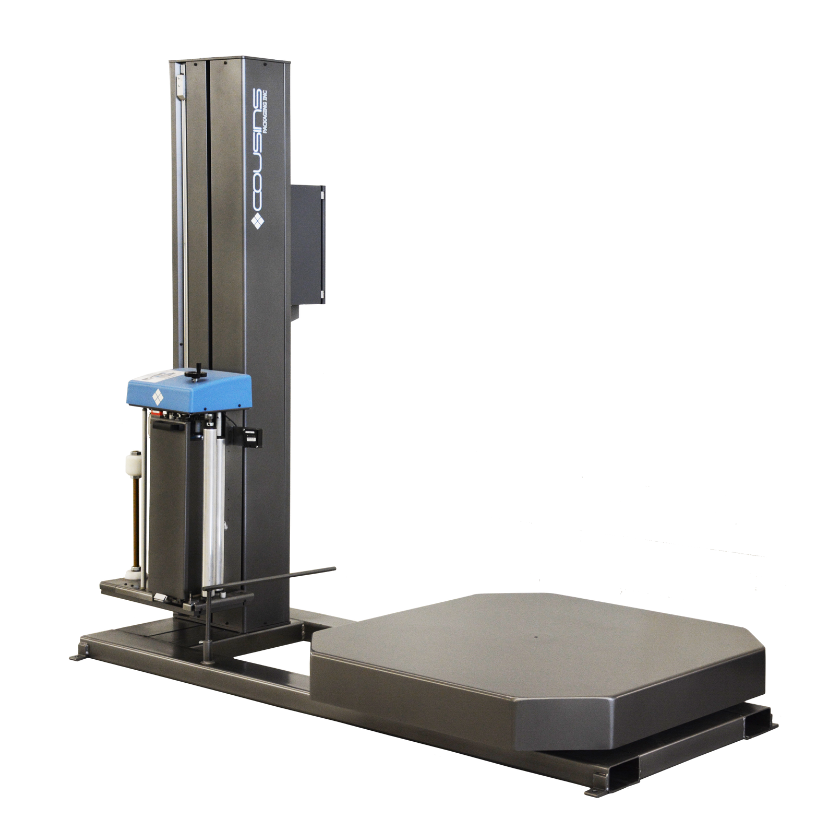

While there is a wide variety of stretch covering devices readily available in the marketplace, top quality designs share certain key features that establish them apart. These machines are generally durable, made to endure considerable use without jeopardizing on performance. They supply a high degree of automation, enabling hassle-free and efficient wrapping of products.

Premium stretch wrapping machines additionally feature flexible setups, offering versatility to match different packaging demands. They can deal with various dimensions and kinds of loads, making sure a safe cover every time. These equipments are additionally renowned for their rate, efficient in covering countless pallets per hour, therefore dramatically increasing productivity.

Another key function is their reliability and low maintenance need. Top quality devices are built to last, minimizing the regularity of malfunctions and the associated downtime. They run with precision, guaranteeing constant cover stress, thus reducing waste and enhancing the presentation of wrapped products.

The Effect of Stretch Wrapping Devices on Warehouse Performance

The effectiveness of a stockroom can be substantially enhanced with making use of high-quality stretch covering devices - stretch wrapping machine. These devices streamline the product packaging process, reducing the hands-on labor involved and consequently, the chance for human mistake. This makes certain a much more regular and trusted wrapping process, leading to improved safety and security of goods throughout transport

Additionally, stretch wrapping makers can take care of a higher quantity of goods in a shorter quantity of time contrasted to hands-on covering. This enhanced performance can cause far better use of warehouse room as items can be packaged and moved faster. The equipments also offer the flexibility to suit different sizes and shapes of products, even more boosting operational effectiveness.

Determining the Return on Investment for a Stretch Covering Device

Taking into consideration the considerable benefits of stretch wrapping makers, it's critical to comprehend the monetary effects of purchasing such devices. The return on investment (ROI) calculation is a simple yet efficient device to analyze the productivity of this financial investment. The ROI is determined by comparing the cost of the equipment with the financial savings produced over a details period.

The greater the ROI, the much more successful the investment. This number must not be the link sole factor in the decision-making procedure. Services must also take into consideration aspects such as critical positioning, operational effectiveness, and scalability. Finally, calculating the ROI provides a clear economic point of view to direct the investment decision in stretch wrapping makers.

Real-world Study: Success Stories of Applying Stretch Covering Machines

Drawing from the monetary ramifications gone over in the previous area, it is similarly enlightening to analyze sensible applications and success stories of firms that have applied stretch wrapping makers in their procedures. One such instance is a multinational electronics business which reported a 30% decrease in damaged products during transit after presenting stretch wrapping equipments in their packaging process.

One more success story involves a leading food and beverage firm. After executing a stretch covering device, they witnessed a substantial enhancement in their packaging hop over to here speed, which consequently boosted daily outputs and total productivity.

Lastly, a prominent furnishings producer had the ability to lower their product packaging material prices by an incredible 40% after switching over to stretch covering devices; they simultaneously lowered their carbon footprint, making their procedures extra sustainable. These real-world situation research studies demonstrate the impressive returns and performance gains that stretch covering equipments can bring to storage facility operations.

Conclusion

To conclude, spending in a premium stretch wrapping machine can considerably boost storehouse operations. With its capacity to lower manual labor, reduce errors, and enhance area application, it significantly enhances efficiency and earnings. The ROI, paired with success tales from real-world applications, even more underscores the crucial function of stretch wrapping machines in attaining functional effectiveness and service success.

The introduction of a top notch he said stretch covering machine can be a game-changer, encouraging efficiency, minimized labor costs, and minimized human mistake.In the huge realm of storage facility procedures, the importance of stretch covering equipments can not be overstated.The performance of a storehouse can be considerably improved with the usage of premium stretch wrapping devices.Additionally, stretch wrapping makers can deal with a higher quantity of items in a much shorter quantity of time compared to manual wrapping.In verdict, spending in a high-quality stretch wrapping machine can substantially improve storage facility procedures.

Report this page